Built in a Factory

Each building is constructed on an 8″ thick mat engineered concrete slab, so strong we can ship a completed building nationwide without damage. Excellent quality control comes from fabricating inside temperature controlled factories.

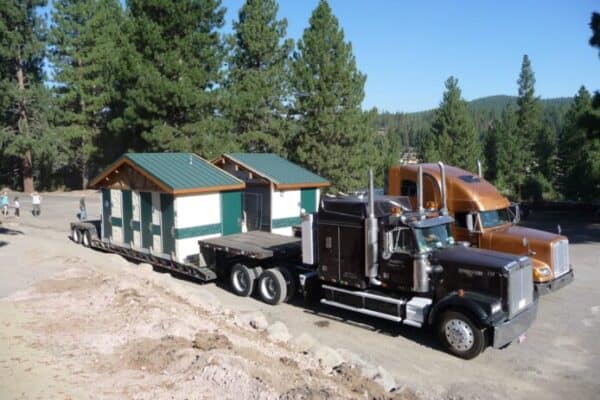

Delivered by Truck

Once construction is complete, each building is shrink wrapped and transported on special heavy-load, air-ride truck trailers to the installation site. Our OSHA certified staff travels nationwide to ensure successful installation for each building.

Installed with a Crane

A crane lifts the prefab structure off the transport trailer and onto a prepared building pad/foundation within a few hours. Our turnkey installation process eliminates lengthy on-site disruptions and potential vandalism that comes with a traditional construction site.

PRC Overview

Installation

Why PRC?

Building Better Places To GoSM

From start to finish, we stand out from the rest of the competition with some notable highlights:

- Design and engineer each building to be safer for the public

- Buildings are easier to maintain with non-absorbent concrete, “no smell” interiors

- Offer three (3) progressive levels of vandal-resistant materials and finishes

- Architecturally flexible to match historical sites and/or nearby buildings

- Engineered to meet building codes in every town, city, state, and park in America

- 40+ years of public restroom design, building, and installation experience

- Typically costs less than site-built construction

Contact us today for all your turnkey, prefabricated public restroom and building needs.

BLOG POSTS

-

Make Your Public Restrooms Do More

July 2, 2025How to incorporate eco-friendly restroom design that blends into the landscape, saves resources, and improves the overall visitor experience....

Read More -

Eco-Friendly Restroom Design: A Smart Choice for Parks

July 2, 2025How to incorporate eco-friendly restroom design that blends into the landscape, saves resources, and improves the overall visitor experience....

Read More -

San Francisco’s “Toiletgate” solved with Prefab

March 22, 2025One of PRC’s biggest and most notable moments from 2024 was just over the mountain pass in the City by the Bay – San Francisco. Last March ’24, Noe Valley......

Read More